Oil and Gas

Connectivity for Each Part of Your Wellpad Application

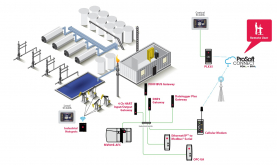

The size and complexity of oil and gas applications make it impossible for users to use one technology or platform. Each part has information that needs to be sent to your PAC or SCADA system, making real-time protocol conversion and data transfer a must. Meanwhile, throughout your wellpad site, wireless connectivity can ensure reliable communications among wide-ranging equipment.

Read moreSeparator Connectivity for Oil and Gas Applications

The separator in wellpad applications requires reliable communications to ensure the separation of oil, gas, and water – and then get these resources where they need to go next.

Read moreCollect and Analyze Oil and Gas Applications’ Production Data with Remote Connectivity Solutions

With remote access solutions, your measurement and production data can be automatically sent to your existing SCADA, host, or headquarters location. From there, the data can be analyzed and corrective actions taken if necessary. The detailed data and activity log that’s automatically generated can also help you meet regulatory requirements.

Read moreConnecting Disparate Systems in Oil and Gas Applications

Oil and Gas automation systems are complex and contain technologies from different vendors and platforms. To operate efficiently, it is critical that these disparate systems exchange data. It is also important to get this data to a central location for analysis with the intent to improve productivity and efficiency.

Read moreIncrease Data Integrity in Your DNP3 Application

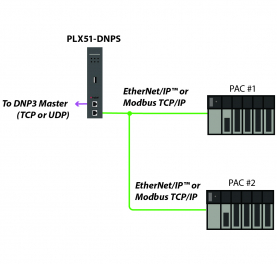

DNP3 is prevalent in utility applications around the world, including in over 90 percent of North America utilities. Its scalable nature and time-stamping at the source provides the data that many companies need to maintain reliable service that can expand as the coverage area grows. ProSoft’s latest DNP3 gateway aims to make that data collection as thorough as possible.

Read moreCellular Considerations for Oil and Gas Applications

Cellular technology can bring many benefits to an oil and gas application. Read this blog post to learn about the considerations to keep in mind when selecting a solution.

Read more