Wireless radios provide the reliability that a rotating machine needs

Wireless radios provide the reliability that a rotating machine needs

It’s a carefully considered process: Ethernet cables are produced in a Bitner facility in Poland. At the main point in the application, one machine is manufacturing twisted cable. Starting with eight wires, the machine twists them off into pairs. The four pairs of cables are then twisted together and bent on the drum. After eight hours, the machine has put together more than 14 kilometers of Ethernet cable. After each cable has been successfully twisted, it’s moved to the coating portion of the application.

Downtime in any application like this one can be financially disastrous, so ensuring that the machine is running efficiently is important. The machine builder, Comprex, was trying to boost the reliability of the communications. The company manufactures machines used in cable production.

Comprex’s goal was to have full control over the rotating portion of the machine, with continuous wireless connections. Other wireless solutions the company had tested so far were not quite up to the task.

Other options were to slow the process down to a speed at which the rotating portion did not interfere with the necessary communications; use slip rings; or redesign the mechanical machine so that it would have cable control on the process.

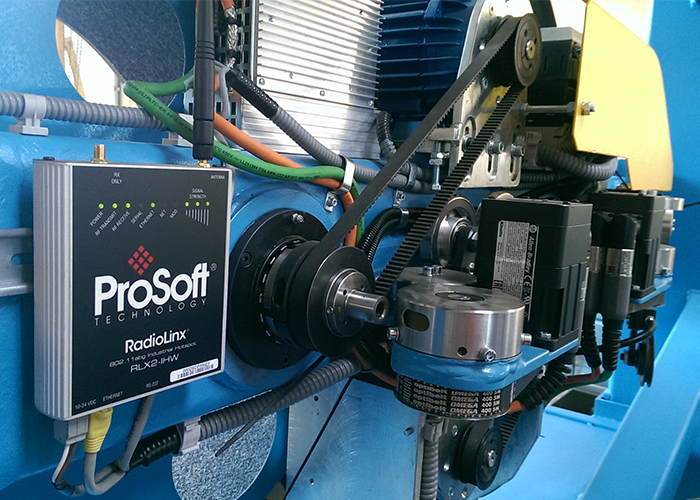

The equipment already in use for the application included a Rockwell Automation® CompactLogix™ 1769-L36ERM, PowerFlex® 525, and Kinetix 300. Discussions between Comprex and representatives from Rockwell Automation and local distributor RAControls led the machine builder to ProSoft Technology’s wireless solutions.

The team from ProSoft Technology helped design the architecture for the project and provided calculations to Comprex. The five Industrial Hotspots used on the rotating part of the cable twister allowed for constant control of the tension on the wires and twisting speed, and also allowed the company to detect broken wires. It brought other benefits as well, including an increase in the machine’s performance and the cables’ quality.

“Comprex liked that our solution was minor in terms of the unit, but impacted the overall machine’s performance,” said Krzysztof Hajzyk, ProSoft Regional Director of Sales and Marketing for Europe.

The gains to the machine builder were many and varied.

“The wireless standard used allows access to all components of the machine from every place in the world over a secure remote access VPN. Usage of CIP over EtherNet/IP™ also provides a unique solution for remote maintenance and diagnostics of the machine,” said Ryszard Jalocha, Senior Automation Systems Designer at Comprex. “It saves costs and allows the development and engineering team to be utilized in a more optimal way.”

Other benefits to the machine builder include the transparency of the wireless system to the protocols sent over it, and the radios allowing them to use standard communications that are already built into the existing system.

The wireless system configuration that ProSoft recommended helps the end user avoid interference with the plant’s network infrastructure and other machines’ communications. Comprex noted that another advantage for Bitner is that all components, including the radios, allow for configuration transfer via an SD card, decreasing downtime in the event of a system issue and streamlining maintenance.

Other benefits to the customer center on the increased performance of the machine as a result of the wireless solutions. Cables are now produced more quickly, and are also higher-quality. The customer has also seen an ease of use in manufacturing the cables: The machine is now allowing the production of different types of cables without having to reset between the different varieties, and all cable types are stored as recipes. After production starts, the machine doesn’t need maintenance/monitoring during the process, which allows the end user to allocate those resources to legacy machines on site.

Learn more about Industrial Wireless Solutions here.