Improving communications – and conserving energy – at a water treatment plant

Improving communications – and conserving energy – at a water treatment plant

There’s a beautiful wooded area close to one of the largest cities in Poland, with about 350,000 residents. In that idyllic spot, a water treatment plant works to provide fresh water from a river to supply lines in the city. The plant luckily has a standard filtration system with the addition of infiltration water treatment. Water production relies on the quality of the water at the river. This means that plant operators have to stay vigilant when it comes to being sure that the system is working properly and that there is enough water in reserves.

On site, there are 116 PLCs, 106 deep wells, six well siphons, three wells with drainage systems, and 13 basins/ponds. Water is pumped from the river to filtration ponds and trenches, before submersible pumps siphon the water. The ponds secure 30 days’ worth of water, and the system even allows them to have a year-round constant temperature for the fresh water. All in all, it’s a well-honed system: The water is aerated and filtered using gravel, sand, and coal, then ozonation and chlorination processes take place before the water is ready to be delivered. An operator controls the flow of the water going to the basin, while geologists use a piezometer, which tests the amount of water at the ground level. If there is more than needed, threshold pumps extract the water to have it put in municipal/city pipes. The piezometers are long-lasting – three to five years per battery – and send information to the server once a day.

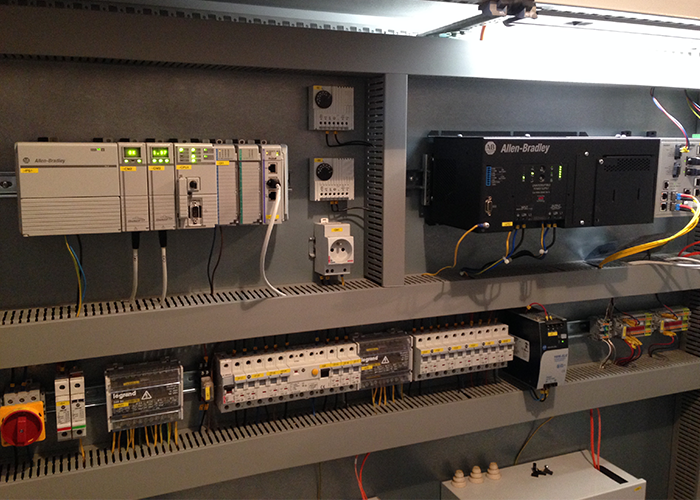

The pumping stations are controlled by 115 controllers. The three main systems are the Rockwell Automation® 1768-L43 CompactLogix™ controllers, while 112 MicroLogix™ 1100 systems are controlling the pumps. The three main PLCs are situated at three buildings equipped with a power supply. Because of that, power characteristics were measured only at those three locations.

The operators of the plant wanted to streamline the process by which they found out about any atypical equipment statuses – and also analyze energy usage more accurately, outside of just the three buildings. Power monitors that use Modbus® would help with that – but they would not be able to communicate with the PLCs on their own.

ProSoft Technology’s modules solved this problem. A Rockwell Automation distributor in Poland – RAControls – suggested ProSoft’s in-chassis Modbus® modules be added to the CompactLogix controllers. An alternative setup involved connecting Modbus devices directly to the SCADA system or using the serial port of the PLC to foster connections, but ProSoft’s modules proved to be a far better solution.

“Not only would they facilitate communication between the RTUs and the controllers, the modules allowed the system to be scalable should the site expand in the future,” said Romuald Piłatowski, RAControls Regional Sales Director. “We also appreciated ProSoft’s commitment to technical support.”

Going into the project, the plant operators knew what they wanted to achieve: Constant control of the process; detection of atypical situations throughout the site; the ability to calculate the costs of water production; and the ability to optimize the energy grid load at peak usage hours, which is a key goal for the customer, since they want to optimize the energy depending on the energy consumption characteristics.

This setup – and the types of information they were looking for – provides a perfect example of a company utilizing the data they can get from a higher level of communications, made possible by an Industrial Internet of Things-based strategy. ProSoft specializes in helping customers extend their Connected Enterprise – the Rockwell Automation concept of getting the right data to the right personnel so they can make the best business decisions to optimize resources. In this case, IIoT benefits materialized in a couple of ways: By detecting any issues early, the plant would be able to minimize downtime and make sure flow efficiency was consistent; by analyzing energy usage, personnel were able to take advantage of non-peak times and also be sure that the residents of this large city still had enough power.

The benefits of this solution didn’t end there.

“It was very easy to implement Modbus RTU functions with this setup,” said Piotr Mendera, RAControls Application Support Engineer. “We also appreciated the level of support from the outset of this project: The ProSoft-dedicated engineer who worked with the distributor provided sample code, and helped with the installation and configuration of the module.”

Thanks to the communications gained through this setup, the residents of the city can be assured of a more reliable water supply.

For more information about ProSoft Technology’s Modbus communication solutions, go to http://psft.com/BRH.