Plant Energy Management

Communication Solutions

|

|

Leverage your existing automation and power systems to begin saving energy more effectively, and using it more intelligently. Whether your energy costs are from water, air, gas, electricity or steam, ProSoft Technology offers a number of solutions to help you manage them in a way that brings meaningful value to your business – by lowering production costs and optimizing profits. |

Why Focus on Energy Costs?

- Energy costs such as electricity, compressed air, natural gas, water and steam are no longer considered as overhead

- To meet corporate sustainability objectives

- To properly allocate energy costs by department, process or facility

- Typical savings when energy costs are optimized are 5-15%

- Lighting accounts for 20% to 25% of all electricity consumed in the United States

- 10% of all electricity is consumed to create compressed air

- 30% of all compressed air generated is never used due to waste and leakage

- At 415 psi, a 1/8” hole will cost $5,800 per year in lost steam

Effective Energy Management

- Collect information about what is actually happening, when it is happening

- Plant-wide overview considering production processes and points of use

What to Measure

- Generators

- Plant substations

- Furnaces/ovens

- Motors

- Air compressors

- Chillers

- Boilers

- HVAC systems

How Can ProSoft Help You Save on Your Energy Costs?

|

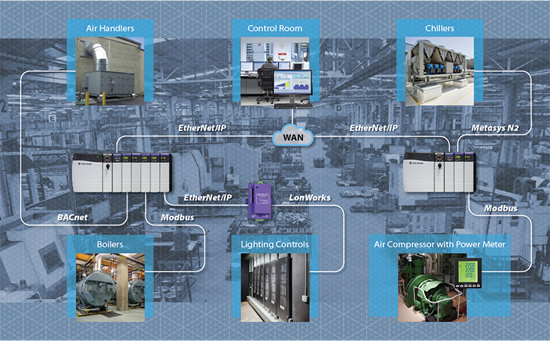

These systems and devices often use protocols such as BACnet, LONworks, Johnson Control Metasys or Modbus. Our PLC in-chassis modules or gateways bring that data into the PLC, where you can monitor and coordinate the control of your energy systems with your production / manufacturing needs. Collecting all this data in the PLC makes it easier to use software tools to analyze your energy usage. The PLCs can then be programmed to coordinate these systems and devices to reduce your energy consumption. |

Modbus/Modbus TCPProSoft Technology was the first company to offer an in-chassis Modbus interface for Rockwell PLCs. We now have in-chassis solutions for Rockwell Automation's ControlLogix and CompactLogix platforms. We have a full line of industrial Modbus gateways that allow you to pass data from devices on networks that use over 30 different protocols. |

Johnson Controls MetasysAvailable for most Rockwell Automation platforms including ControlLogix, CompactLogix, SLC and as a stand-alone gateway. |

LonWorksAvailable for Rockwell Automation ControlLogix, and as a stand-alone gateway. |

BACnetDesigned for Rockwell Automation’s ControlLogix platform and as stand-alone gateways, these modules enable the exchange of information between BACnet Master devices such as Trane BCU and Alerton Controllers or BACnet slave devices such as VSD, lighting controls, and AC controls. |