Getting familiar with PROFIBUS redundancy

Getting familiar with PROFIBUS redundancy

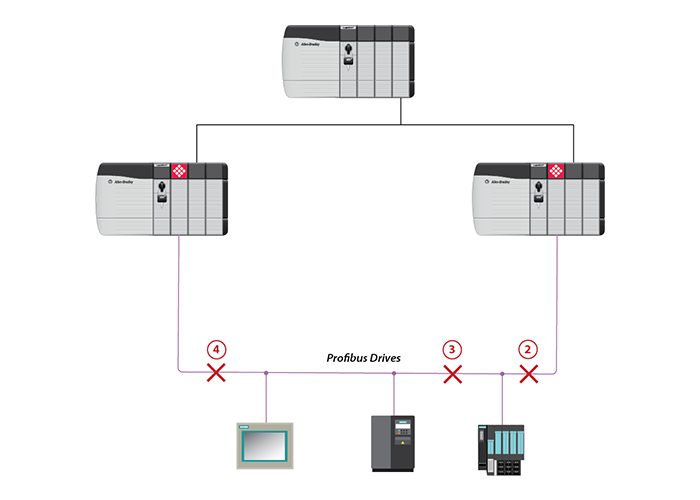

PROFIBUS redundancy is not native for ProSoft’s PROFIBUS solutions. The below example, done for ProSoft’s PROFIBUS master ControlLogix® solution, is showing how redundancy can be managed.

This sample can be adapted to all of ProSoft’s PROFIBUS Master solutions (ILX56-PBM, ILX69-PBM, PLX51-PBM).

Required material:

• x2 ILX56-PBM

• ControlLogix hardware (Chassis, PSU, CPU, EtherNet/IP adapter…)

• PROFIBUS Slave devices

Optional material:

• Redundant PLC architecture

Usage (with above cabling):

1. Communication is running fine, all slaves are visible by ILX56-PBM (MVI_1), which is the active master. MVI_2 is deactivated.

2. If the cable is cut between MVI_1 and Slave 1: The MVI_1 will see no slave; this is visible in the status of the module. The MVI_2 can be activated to check that it can see all the slaves; if so, the MVI_1 can be deactivated and MVI_2 can remain the only master on the network. This will give time to perform maintenance operations on the PROFIBUS connection.

3. If the cable is cut between Slave 1 and Slave 2: The MVI_1 can communicate with Slave 1 but not with the others. The MVI_2 can be activated to check that it can see the other slaves; if so, both modules can be active on the network. This will give time to perform maintenance operations on the PROFIBUS connection. The function is the same regardless of the number of slave devices that are available for the two ILX56-PBM modules.

4. If the cable is cut between Slave N and MVI_2: If the MVI_2 is the active master, the MVI_2 will see no slave. The MVI_1 can be activated to check that it can see all the slaves; if so, the MVI_2 can be deactivated and MVI_1 can remain only one master on the network. This will give time to perform maintenance operations on the PROFIBUS connection.

Activation and deactivation of the ILX56-PBM modules can be done via the ladder logic. Control of the ILX56-PBM status information is necessary to verify the connection state of the slave devices. Input data is updated when the ILX56-PBM module is activated. Output data has to be copied in ILX56-PBM at any time to insure that the output data is always up to date. The customer application must decide which data is to be used.